Why Mactenn

Technology

Low Velocity

Our proprietary technology, designed and manufactured in-house, excels due to our expertise in low-velocity pneumatic conveying. Low-velocity, dense phase pneumatic conveying is the preferred method for handling many difficult-to-convey, fragile, and abrasive materials. To prevent material degradation and wear, these materials are conveyed at very low velocities of 1-3 metres per second.

The main benefits of low velocity conveying are:

- Low air and energy consumption

- No or minimal material degradation

- No or minimal component, pipe and bend wear

- No or minimal material segregation

Experience

Our experience spans nearly every process industry, from food to minerals, combustion to chemicals, and more. We have mastered the ability to handle thousands of materials, from pebble lime to peanuts, biomass ash to baby powder, and many others.

Design

Our systems are designed with quality, flexibility, reliability, and efficiency in mind. We recognise that every requirement is unique; therefore, our equipment is designed to accommodate various needs. Our systems come in different sizes, materials of construction, control options, and design pressures, and can handle temperatures up to 350°C and higher with special design considerations.

We offer a wide range of proprietary ancillary equipment, such as bends, switch valves, diverters and other components to complement our pneumatic conveying equipment. Once a scope has been agreed upon, we can also provide installation services.

Characteristics of Our Designs:

- Low maintenance with only one moving part

- Robust proprietary Inflatek™ Valve

- User friendly with simple operations and fully automated controls

- Only a few spare parts required

- Limited downtime

- No pipeline air boosters

- Simple installation and retrofit

Quality

Due to our extensive experience and focus on quality, we offer a 24-month warranty (terms and conditions apply), which exceeds the standard industry warranty of 12 months. This extended warranty provides significant benefits and adds real value for our customers.

Service

Our customer service excels for many reasons.

- Experienced technical support

- Replacement parts readily available

- Commissioning and field service support

- Factory refurbishments

- Application engineering for retrofit of equipment

- Operations and maintenance personnel training

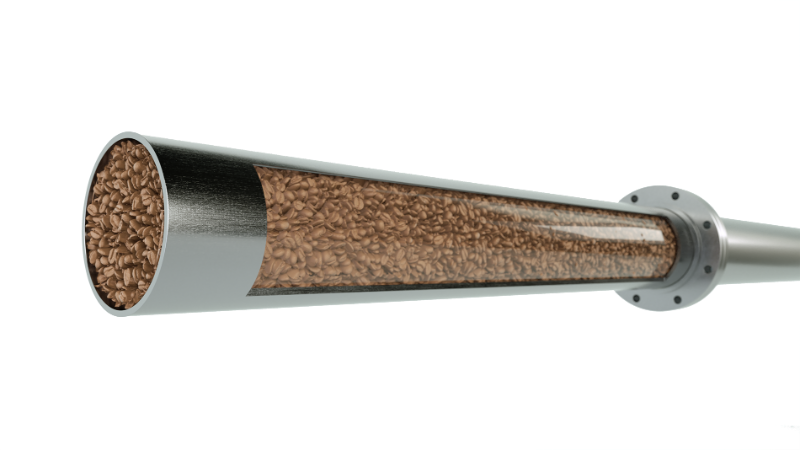

Dense Phase – Full Pipeline

The difference in pressure is higher

Material velocities are at their lowest

Material fills the pipeline

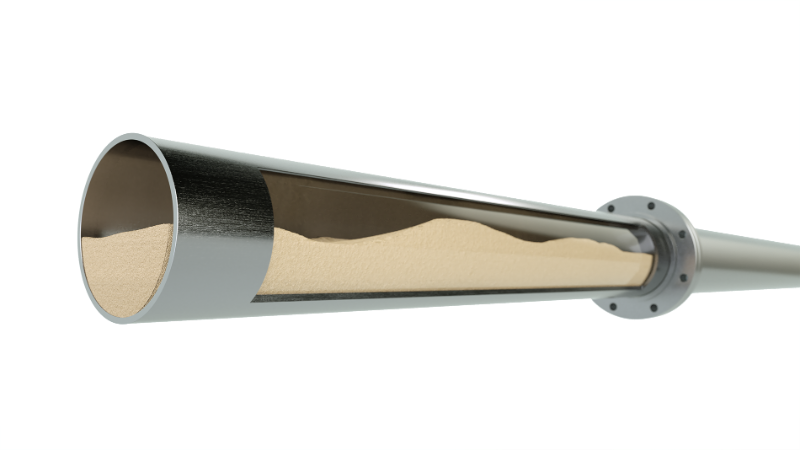

Dense Phase – Slug Flow

The difference in pressure is medium-high

Material velocities are low

Material forms dunes while being conveyed

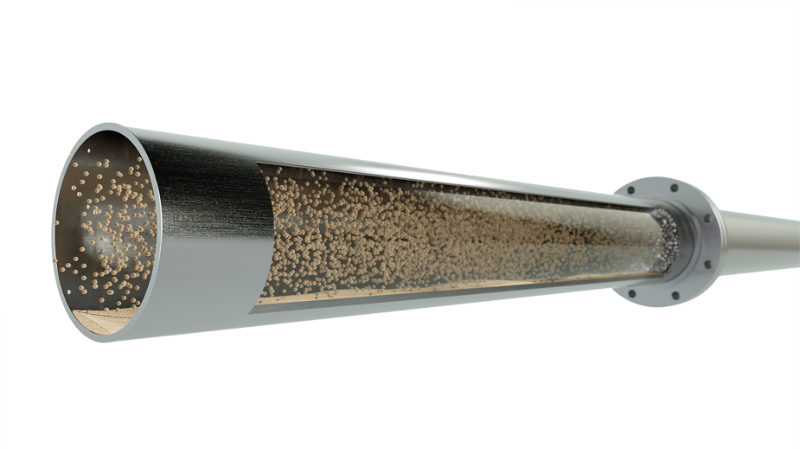

Dense Phase – Bed Flow

The difference in pressure is medium

Material velocities are medium to high

The saltation velocity is achieved for some particles in the material which partially fluidises to convey above a bed of material moving slower

Lean Phase (Dilute Phase)

The difference in pressure is lower

Material velocity is highest

The saltation velocity for all the particles is achieved which causes the material as a whole to be conveyed within the gas stream

Material Handling

Bulk materials presents unique challenges to all industries involved, but today’s environmental standards bring the need for reassessment and changes in perspective. Some companies work with materials that are so hazardous that any loss of material while it is being transferred is a threat to employees as well as the surrounding environment. Mactenn has the answer: totally enclosed transporter systems, which make material handling so much easier and more efficient. Our dustless conveying technology has benefited thousands of clients facing the hurdles of retrofitting existing plants or having to start from the ground up.

Mactenn Systems General Material Handling

Mactenn has conveyed thousands of bulk materials in various industries. Whether the material nature is abrasive, explosive, hazardous, hygroscopic, dense, fragile, or hot, we offer a gentle conveying solution for the most optimal results. Our conveying systems present efficiencies that are timeless to the ever-evolving process needs.